Vacuum Insulated Pipe (VIP)

Rigid Vacuum Insulated Pipes

CSM rigid Vacuum Insulated Pipes (VIP) are engineered to deliver superior thermal efficiency and long-term reliability for the transfer of cryogenic fluids. Utilizing advanced super-insulation technology, VIP systems are suitable for a wide range of cryogens, including liquid nitrogen, oxygen, argon, helium, hydrogen, and LNG.

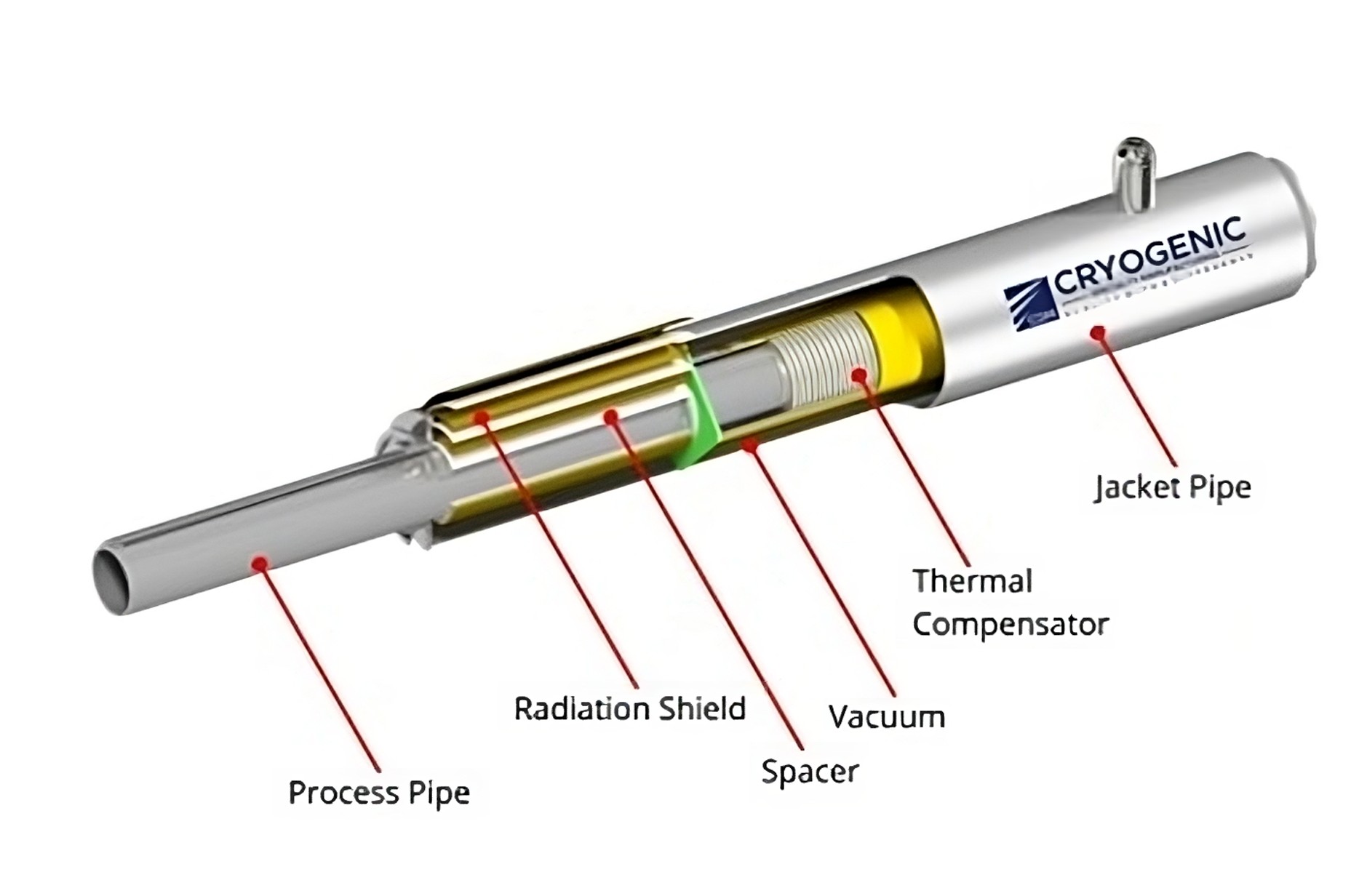

Each vacuum insulated pipe consists of a dual-wall stainless steel construction: an inner carrier pipe for cryogenic fluid transfer and an outer jacket that maintains a high-quality vacuum environment. The inner pipe is wrapped with multi-layer insulation (MLI) and integrated with hydrogen getters and molecular sieves to preserve long-term vacuum integrity and insulation performance. This “vacuum jacket” design significantly minimizes heat ingress, reducing thermal losses and improving overall system efficiency.

To learn more about the engineering principles behind vacuum insulation and thermal efficiency, visit our Cryo-Blog: (1) Super-Insulation, (2) Heat Leaks, (3)Thermal Conductivity, (4) Value vs Cost

Key Features and Benefits

-

Superior Vacuum Insulation: Effectively minimizes heat loss and product boil-off, lowering operating costs while maximizing thermal efficiency

-

Reduced Cool-Down Losses: Lightweight construction with low heat mass shortens cool-down times during startup and reduces product loss during maintenance or system downtime

-

Frost and Condensation-Free Connections: Precision-engineered bayonet connections and super-insulated field-welded joints ensure frost-free, condensation-free operation for long-term reliability

-

Ease of Integration: Pre-engineered modular spool designs simplify installation, reduce site work, and streamline maintenance

- 10-year Vacuum Warranty: Industry-leading vacuum warranty ensures confidence, durability, and long-term performance

Configuration & Flexibility

CSM Rigid Vacuum Insulated Pipes are available in sizes ranging from ½” to 12” NPS, with lengths of up to 12 meters (40 ft). Options include internal or external expansion joints and a wide variety of end connections, such as bayonets, vacuum- or foam-insulated field-welded joints, flanges, threaded connections, flared fittings, and custom interfaces. For added system flexibility, integrated flex sections can be incorporated to accommodate thermal expansion, offsets, expansion loops, and use-point transitions.

Applications

-

Electronics & Semiconductor

-

Medical & Pharmaceutical

-

Laboratory & Biotechnology

-

Food & Beverage

-

Aerospace

Engineering & Technical Support

Our trained and certified engineers support you throughout the entire project lifecycle, including:

-

System troubleshooting

-

System audits & safety consultation

-

Field measurement and system layout

-

Project management

-

System design & process integration

-

Installation & commissioning