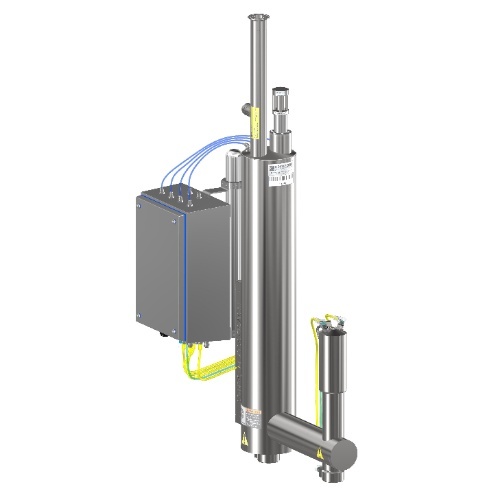

Welded Connection

Welded Connection, W-series

CSM uses a highly efficient field-welded cryogenic connection for vacuum insulated piping systems. Vacuum insulated welded connection ensures leak-free welded joint with lowest heat leak by providing a continuous vacuum insulation between the spool sections. Constructed in stainless steel either 304L or 316L, the vacuum insulated welded connections are designed with high-quality long heat path transition to be installed with our standard low profile sleeve tube. These design features translate to lowest heat leak and preserve liquid cryogen quality.

Fully welded connection ensure full working pressure up to 35 Bar and is recommended for application where leak free and process safety are paramount, such as in the field of new energy with flamable process media like liquid hydrogen and LNG. It is also suitable for extreme hazardous and vibrative working environment like petrochemical complex, ASU plant and Fuel Bunker system. Connection insulation can be done either by low heat leaks vacuum insulation or polyurethane foam insulation subject to heat leak demand from each individual application.

Features and Benefits

- Virtually leak free, helium leak tested < 1 x 10-9 cc/s.atm

- Frost and condensation free connections

- Minimization of heat leak

- Easy to install at compact working spaces

- Can be installed in any orientation

- Welded connection ensures high durability & vibration resistant

- Available in Vacuum jacketed or Polyurethane insulation options

Product Cutsheet: