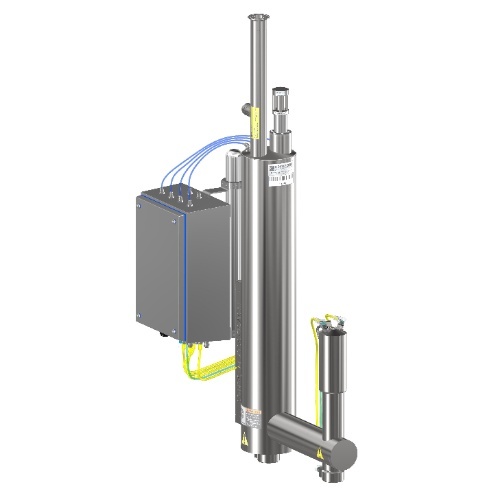

Automatic Dewar Filling System

Automatic Dewar Filling ADF10 for unattended liquid nitrogen filling. This system is designed to automatically fill a dewar/mobile tank with liquid nitrogen from a piping system or bulk tank.

- Automatic shut off for unattended filling

- Fastest filling rate compared to any products in the market

- Equipped with a user defined safety timeout feature

- Provides a true liquid nitrogen fill

- Eliminates liquid nitrogen waste

Here are some key advantages of ADF10:

- Offers alternative filling using user-defined timeout based on Dewars capacity, ensuring accuracy, while providing flexibility for customized dewar filling.

- Includes a safety leak check before filling, preventing operator injuries due to leaking liquid nitrogen from poor fittings.

- Uses a Thermistor sensor instead of thermocouple. Thermistors experience such a large change in resistance per °C, which enables ADF10 to accurately differentiate cryogenic phases between liquids and vapor, allowing instant and accurate detection of liquid presence in vapor vent line to prevent dewar overfilling hazard.

- Provides multiple inputs to override system automatic filling by external devices, including O2 safety monitoring systems, liquid weight measurements, liquid leak detection sensors, and emergency shutdown manual override capabilities.

- 24VDC dry output to connect auxiliary equipment like EMO valves or audible/visual alarms for emergency evacuation.

- Incorporates a PLC and user interface display panel, providing visual text displays of alarm conditions or diagnostics situations.

Specifications :

- Rated input voltage : 85 – 264VAC

- Maximum Feed Supply Pressure: 300 PSIG (20.0 BAR)

- Maximum filling rate : 10LPM

Product Cutsheet: