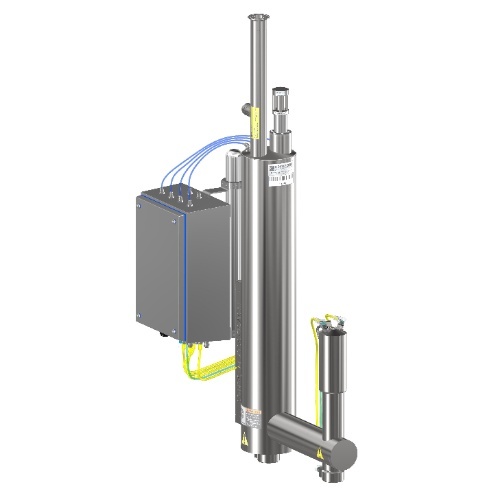

Phase Separator

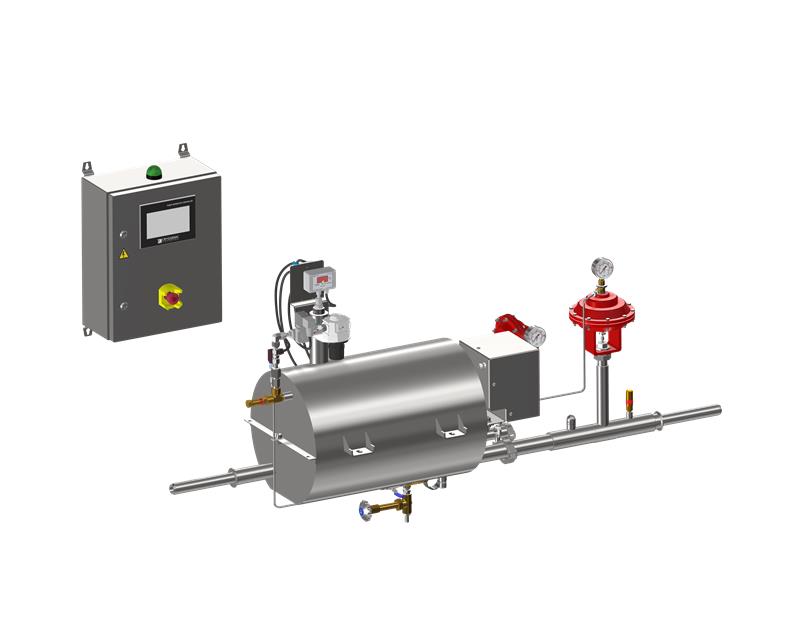

Phase separator is designed to control LN₂ pressure at the user's required setting. Once the system has been set up, liquid level and pressure are automatically controlled by the controller. The controller comes with an HMI that allows the user to set their required pressure and level.

Primary Function of the Phase Separator

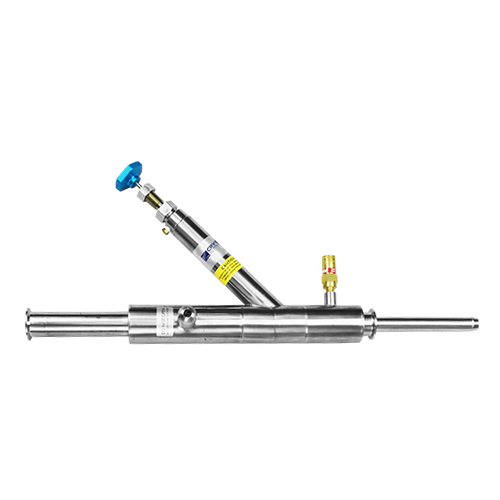

- Reduce the higher liquid nitrogen saturation pressure in the bulk tank to a lower pressure at the user point of use (POU).

- Remove excess gas developed in the liquid nitrogen pipelines due to heat leaks.

- The way it works is that higher pressure liquid nitrogen flows into the vessel and undergoes phase separation due to a sudden change in volume.

- The gas is vented out to the atmosphere while the liquid is kept in the storage vessel at a desired set point pressure for delivery to the POU.

The CSM phase separator is super-insulated to minimize thermal heat transfer and reduce liquid nitrogen boil-off to below 0.45L per hour, with a heat flux of no more than 20W.

There are two primary models to choose from:

- pressure adjustable

- atmospheric pressure type.

The CSM Phase Separator is available in various vessel storage capacities

- 22 liters

- 46 liters

- 76 liters

Configurable with 1 to 12 liquid outlets, depending on application needs

.jpg)

Pressure Adjustable

.jpg)

Atmospheric Pressure