Subcooler

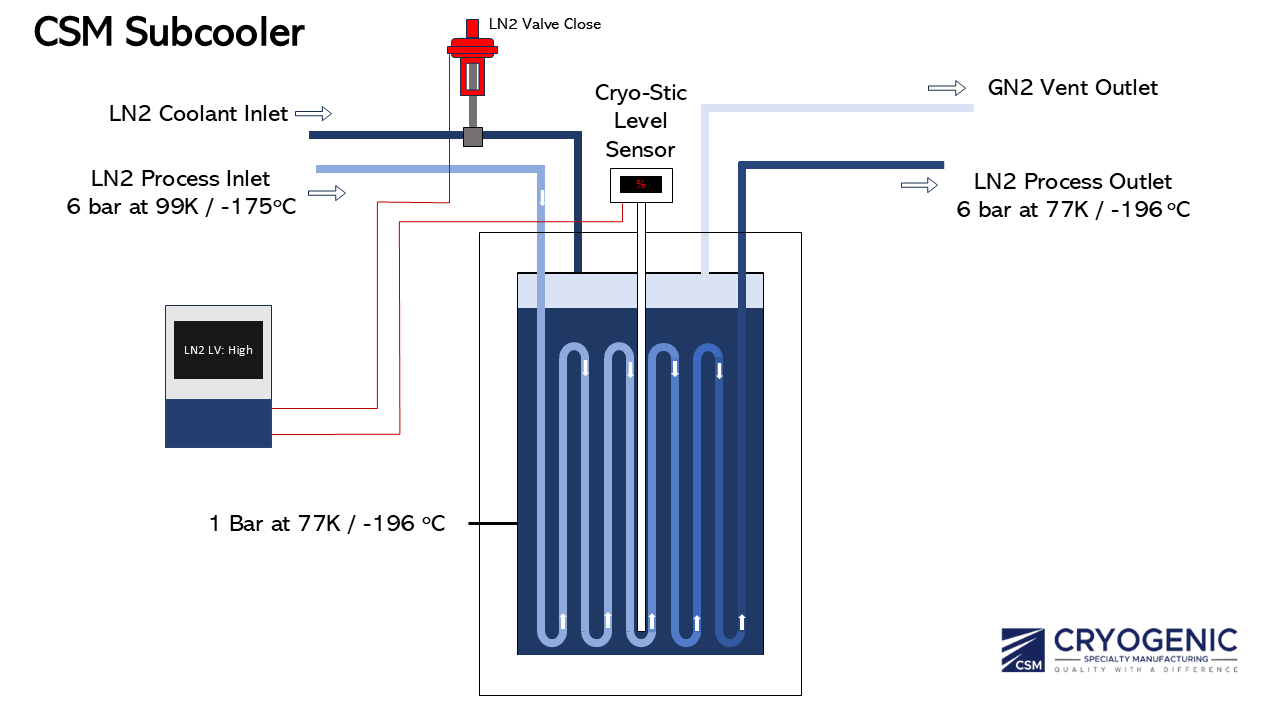

The cryogenic subcooler is a specialized system that ensures liquid nitrogen (LN₂) and other cryogenic liquids remain at a stable, subcooled state during use. By preventing vapor bubbles and pressure fluctuations, it guarantees smooth, reliable, and safe delivery of cryogenic liquids into your process.

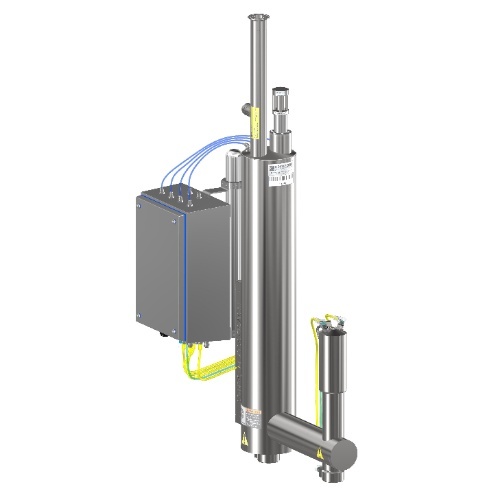

CSM Subcooler is designed to eliminate vapor, maintain line pressure (up to 10 bar), and handle flow rates as high as 3,500 kg/hr. It’s built with vacuum insulation and engineered for long-term, worry-free operation.

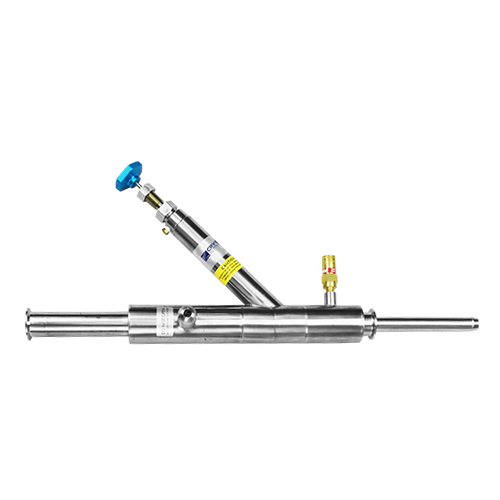

The Subcooler is modular and pre-engineered for easy installation within a piping system.

A subcooler works by lowering the temperature of a cryogenic liquid below its saturation temperature at a given pressure. In transfer pipelines, liquid nitrogen for example, tends to absorb heat and partially flash into gas. By passing the liquid through the subcooler, it removes the excess heat, returning the fluid to a fully liquid state. This minimizes vapor formation, improves flow stability, and increases transfer efficiency.

The subcooler achieves this while maintaining the same pressure as the inlet. Only heat is removed, not pressure, so the liquid nitrogen can be cooled down to around −196 °C while still remaining at its original pressure. This ensures the fluid is denser, more stable, and ready for efficient downstream use.

Key Benefits

- Maximized Freezing Efficiency: Subcooled LN2 is entirely liquid, so a much higher percentage makes contact with the product, absorbing heat efficiently and reducing LN2 consumption.

- Superior Product Quality: Rapid, uniform freezing is the key to preserving food quality.

- Reduced Operational Costs: Use less LN2 to freeze the same amount of product, achieving a lower cost-per-kilo and a stronger bottom line.

- Eliminates Bulk Tank Variable Conditions: Tank pressure and level fluctuations, deterioration in Net Evaporation Rate (NER), inconsistence liquid quality during delivery top-up

Applications

- Food Freezing: In poultry, seafood, and ready-to-eat products, subcooled liquid nitrogen provides rapid and uniform freezing. Because less vapor is formed, more of the nitrogen is available in liquid form, delivering higher freezing efficiency, better product texture, and reduced operating cost.

- Biopharmaceutical Lyophilization and blast-freezing: In freeze-drying for vaccines, antibodies, and other sensitive biologics, subcooled LN2 is critical for the ultra-rapid blast-freezing stage. It enables a consistent, ultrafast temperature drop that forms a fine ice crystal matrix, preserving the delicate molecular structure and potency of the life-saving product.

- Exothermic Chemical Reactor Cooling: Subcooled LN2 provides immense, instantaneous cooling capacity, enabling stable temperature control for exothermic reactions, ensuring process safety with ultra-fast and precise heat removal, prevent thermal runaway and product quality.

-

Precision Cryogenic Machining of super-alloys: subcooled LN2 extends tool life, allows for higher machining speeds, and prevents heat-induced metallurgical changes, ensuring precise part geometry and superior surface finishes for material like Inconel and titanium

-

Nuclear Reactor Emergency Cooling: Subcooled cryogenic fluids provide an ultra-fast and massive heat sink for emergency shutdown and core cooling scenarios preventing catastrophic system failure.

Click here for more detail at CSM Cryo Blog