NovoDoser Overview

NovoDoser Revolutionizing LN2 Dosing

As the demand for LN2 dosing surges, technological advancements are revolutionizing precision and efficiency in the field. NovoDoser, a next-generation high-performance LN2 doser designed for the packaging industry, incorporates groundbreaking innovations in liquid nitrogen sub-cooling technology, advanced nozzle blanketing, and precise dose timing and volume synchronization. These features ensure consistent liquid nitrogen density and uniform dose volumes, delivering exceptional dosing accuracy.

Discover more about NovoDoser's technological breakthroughs on Cryo-Blog:

2. Dose Timing and Volume Synchronization

Please log in to our dedicated website for more product information www.NovoDoser.com

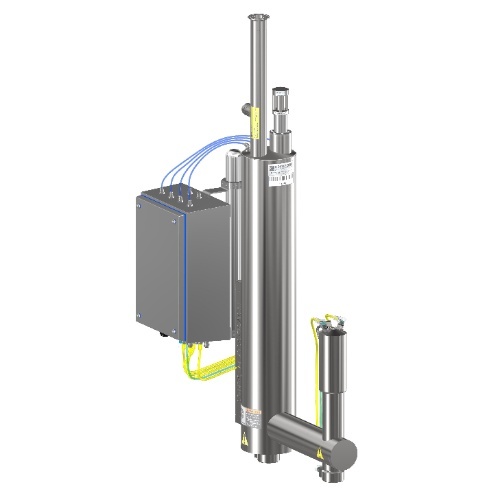

NovoDoser Series

Standard Production

NovoDoser Model Comparison

| Series | M | L | L | L | H | Q |

| Model | 150FD | 250FD | 500SC | 1000DSC-X | 1000DSC-X | 2000DSC-X |

| Head Pressure | 0.18 psi | 0.3 psi | 0.3 psi | 0.3 psi | 0.55 psi | 1.05 psi |

| Body Dimension (H x W) | 23.6 x 3.5" (600 x 88.9 mm) |

33 x 5" (850 x 129 mm) |

33 x 5" (850 x 129 mm) |

33 x 5" (850 x 129 mm) |

42 x 5" (1070 x 129 mm) |

56 x 5" (1474 x 129 mm) |

| Body Weight | 14 lbs (6.3 kg) |

30 lbs (14 kg) |

30 lbs (14 kg) |

30 lbs (14 kg) |

35 lbs (16 kg) |

77 lbs (35 kg) |

| Dosing Head Arm Reach | 6" (150 mm) |

18" (457 mm) |

18" (457 mm) |

18" (457 mm) |

18" (457 mm) |

31" (788 mm) |

| Steady State Consumption | < 0.023 GPH (< 0.09 LPH) |

< 0.026 GPH (< 0.1 LPH) |

< 0.026 GPH (< 0.1 LPH) |

< 0.026 GPH (< 0.1 LPH) |

< 0.029 GPH (< 0.11 LPH) |

< 0.035 GPH (< 0.13 LPH) |

| HMI (LCD Color Touchscreen) | 4.3" | 4.3" | 7.0" | 7.0" | 10.0" | 10.0" |

| Standard Dosing Actuator / Optional | Standard Pneumatic (SB) / Electric (EA) |

Electric (EA) | Electric (EA) / Pneumatic (HS) |

Pneumatic (HS) / Servo (ES) |

Pneumatic (HS) / Servo (ES) |

Servo (ES) / Pneumatic (HS) |

| Dose Duration, 1 ms interval | 10 to 1500 ms / 25 to 1500 ms |

25 to 1500 ms | 25 to 1500 ms / 10 to 1500 ms |

10 to 1500 ms / 5 to 1500 ms |

10 to 1500 ms / 5 to 1500 ms |

5 to 1500 ms / 10 to 1500 ms |

| Dose Volume, mg/dose | 10 to 1400 ms / 25 to 1400 ms |

25 to 1400 ms | 25 to 1400 ms / 10 to 1400 ms |

10 to 1400 ms / 5 to 1400 ms |

10 to 1400 ms / 5 to 1400 ms |

5 to 1400 ms / 10 to 1400 ms |

| Dose Accuracy | ± 4% | ± 3% | ± 2% | ± 2% | ± 2% | ± 2% |

| Max. Discrete Dosing | 250 CPM | 500 CPM | 1000 CPM | 2000 CPM | 2000 CPM | 2000 CPM |

| Continuous Dosing Line Speed | 500 CPM | 2000 CPM | 2000 CPM | 2000 CPM | 2000 CPM | 2000 CPM |

| Dosing Actuator Isolation Valve |  |

|||||

| Dynamic Dose |  |

|

||||

| Fixed Delay |  |

|

|

|

|

|

| Dose Timing Synchronization |  |

|

Sync with Filler |  |

||

| Dose Volume Synchronization |  |

|

Sync with Filler |  |

||

| Encoder Compatible |  |

|||||

| Nozzle Blanketing |  |

|

|

|

|

|

| Thermo-Purging - Quick System Purging - Rapid Nozzle Defrosting - CIP Protection |

|

|

|

|

|

|

| Nozzle Pre-Cooling | Manual | Manual | Auto | Auto | Auto | Auto |

| Filler Command Signal |  |

|

|

|

|

|

| Filler Signal Exchange |  |

|

|

|||

| Modbus RTU User Interface |  |

|

|

|

|

|

| Mobile Remote Monitoring (LAN) |  |

|||||

| Smart Maintenance |  |

|||||

| IoT 4.0 Ready |  |

|||||

| Recipe Storage | 1 | 5 | 5 | 12 | 12 | 20 |

Quick Enquiry Submission!

Submit your enquiry here or scan the QR below - it only takes a minute!

.jpg)