Unlocking Efficiency and Stability in LN2 Systems

14 September 2025

In the world of cryogenic processing, consistency is king. Whether you’re flash-freezing seafood, stabilizing a chemical reaction, or preserving a vital vaccine, the stability and state of your liquid nitrogen are paramount. A common challenge arises: as liquid nitrogen travels through transfer lines, it absorbs ambient heat, causing it to partially vaporize into a inefficient two-phase fluid (a mixture of liquid and gas). This unstable state can wreak havoc on process efficiency, product quality, and operating costs.

This is where the vertical subcooler comes in—a precision conditioning unit designed to solve this exact problem. Let's explore how this unsung hero of cryogenics works and why it's a critical investment for optimizing performance across industries.

What is a Subcooler and How Does It Work?

At its core, a subcooler is a heat exchanger designed for one specific task: to lower the temperature of a cryogenic liquid below its saturation point (its boiling point) at a given pressure.

Think of a glass of ice water at 0°C—it’s in a state of equilibrium between solid and liquid. Now, imagine cooling that water further to -2°C while keeping it liquid. You’ve "subcooled" it. A subcooler does the same for liquid nitrogen.

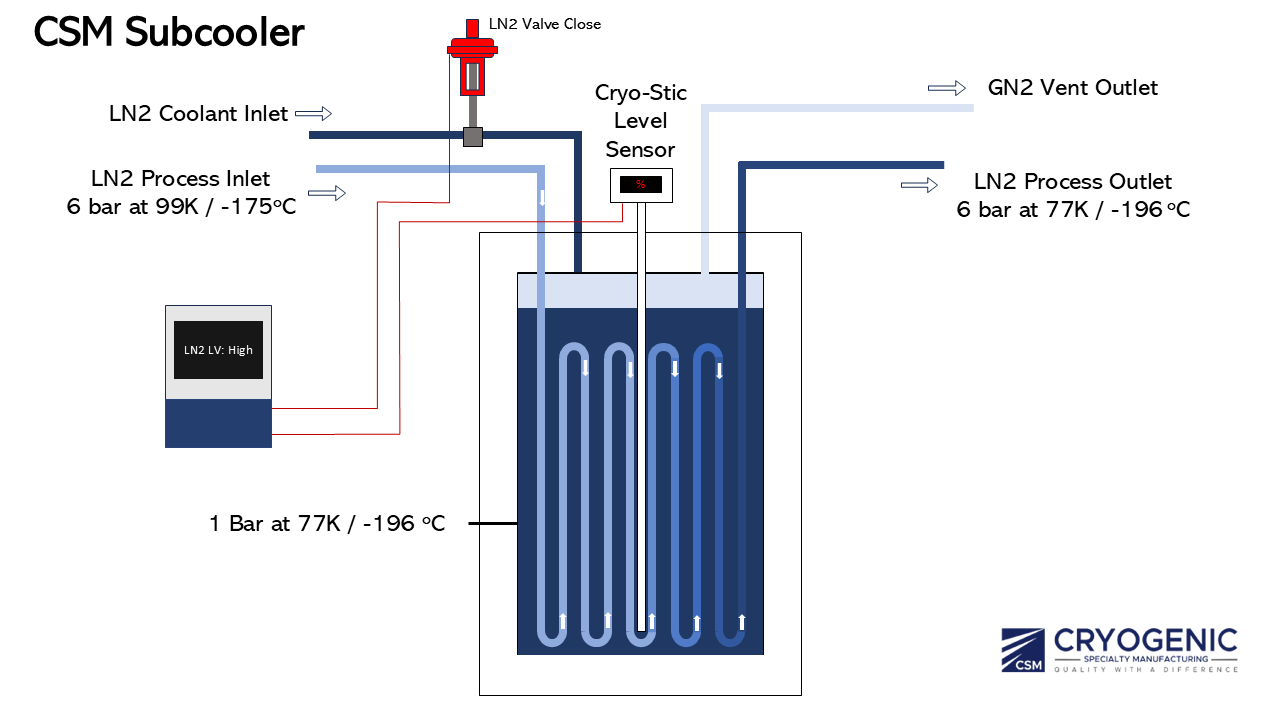

Here’s the process:

-

Warm, Two-Phase Inflow: Liquid nitrogen enters the subcooler’s internal coil. After traveling through pipelines, it has absorbed heat and is now a turbulent mix of liquid and flash gas.

-

Atmospheric Bath Heat Exchange: The core of the subcooler is an atmospheric liquid nitrogen bath heat exchanger. The warm internal coil is submerged in a bath of ultra-cold, atmospheric-pressure liquid nitrogen sourced directly from the storage tank

-

Heat Extraction: The heat from the warm incoming liquid in the coil is efficiently transferred into the calm, boiling bath. This process removes the excess enthalpy (heat energy), condensing any flash gas back into a liquid.

-

Stable, Single-Phase Outflow: The result is an output of 100% liquid nitrogen that is now subcooled, denser, and in a stable single phase, ready for precise downstream application.

The Key Advantage: Stable Liquid, Stable Pressure

A critical feature of the subcooler is what it does not do: it does not drop the pressure.

-

Inlet Pressure = Outlet Pressure: The subcooler is a passive heat exchanger, not a pump or regulator. It removes only heat, leaving the system pressure unchanged.

-

Denser Fluid: By cooling the liquid without changing its pressure, the fluid becomes denser. This means you are moving more mass per unit volume, enhancing transfer efficiency.

-

Eliminates Vapor Lock: The single-phase liquid output ensures smooth, predictable flow, eliminating the pulsations and pressure surges caused by flash gas formation. This protects sensitive equipment like valves and mass flow meters.

Why Subcooling is a Game-Changer: Four Key Benefits

The benefits of subcooling are most dramatically seen in food freezing applications for poultry, seafood, ready-to-eat meals, and bakery products.

-

Maximized Freezing Efficiency: When un-subcooled LN2 hits a product, a significant portion (often 15-30%) immediately flashes to gas, contributing very little to the freezing process. This "wasted" nitrogen simply vents away. Subcooled LN2 is entirely liquid, so a much higher percentage makes contact with the product, absorbing heat efficiently and reducing LN2 consumption.

-

Superior Product Quality: Rapid, uniform freezing is the key to preserving food quality. Subcooled LN2 provides instant and even heat extraction, leading to:

-

Smaller Ice Crystals: This prevents cellular damage, preserving the product's texture, moisture, and nutritional value.

-

Reduced Freezer Burn: Faster freezing minimizes moisture migration.

-

Excellent Product Appearance: It maintains the original shape, color, and integrity of delicate items.

-

-

Reduced Operational Costs: By improving the thermal efficiency of your nitrogen usage, a subcooler directly lowers your operating expenses. You use less LN2 to freeze the same amount of product, achieving a lower cost-per-kilo and a stronger bottom line.

-

Unwavering Process Consistency: This is a critical advantage. A subcooler eliminates the negative effects of variable bulk tank conditions. It ensures your process is completely independent of:

-

Tank pressure fluctuations

-

Liquid level (e.g., low level leading to a higher Net Evaporation Rate (NER)

-

Liquid quality changes during delivery top-up

-

Weather/ambient temperature changes by delivering a consistently cold, single-phase liquid regardless of the tank's state, the subcooler guarantees identical freezing performance 24/7, eliminating a major source of process variation and quality uncertainty.

-

Beyond Freezing: Other Critical Applications

While food freezing is a primary application, the benefits of a stable, single-phase liquid extend to other industries where precision, reliability, and extreme cooling are paramount:

- Biopharmaceutical Lyophilization: In freeze-drying for vaccines, antibodies, and other sensitive biologics, subcooled LN2 is critical for the ultra-rapid blast-freezing stage. It enables a consistent, ultrafast temperature drop that forms a fine ice crystal matrix, preserving the delicate molecular structure and potency of the life-saving product.

- Exothermic Chemical Reactor Cooling: Highly reactive chemical processes require ultra-fast and precise heat removal to maintain control and prevent thermal runaway. Subcooled LN2 provides immense, instantaneous cooling capacity, enabling stable temperature control for these exothermic reactions and ensuring both process safety and product quality.

- Precision Cryogenic Machining: In the machining of super-alloys (e.g., Inconel, titanium), subcooled LN2 is delivered directly to the cutting tool and workpiece. This extreme cooling extends tool life, allows for higher machining speeds, and prevents heat-induced metallurgical changes, ensuring precise part geometry and superior surface finishes.

- Nuclear Reactor Emergency Cooling: As a critical safety component, systems utilizing subcooled cryogenic fluids can provide an ultra-fast and massive heat sink for emergency shutdown and core cooling scenarios. The density and stability of the subcooled liquid ensure immediate and effective heat absorption, a vital function in preventing catastrophic system failure.

- Aseptic Dosing Systems: Provides the precise, vapor-free liquid required for accurate dosing into bottles and containers in beverage and pharmaceutical packaging.

- Blanketing & Inerting: Delivers a dense, liquid stream for creating protective atmospheres in chemical vessels and food packaging.

Conclusion: Invest in Stability, Reap the Rewards

A vertical subcooler is more than just an accessory; it’s a strategic upgrade that transforms your liquid nitrogen from an unstable variable into a predictable and powerful tool. By delivering a denser, colder, and single-phase liquid, it unlocks new levels of efficiency, product quality, and cost savings while insulating your process from the inherent variability of bulk storage.

In an industry where precision, repeatability, and profit margins matter, the subcooler provides a clear and rapid return on investment, making it an essential component for any serious cryogenic operation.

Ready to eliminate flash gas and stabilize your process? Our engineers specialize in integrating vertical subcoolers into existing systems to maximize efficiency, ensure consistency, and reduce operating costs.

Contact us today to discuss your application and calculate your potential savings. Visit us at

- DrinkTec 2025 | Booth A5-310, to see our range of conditioning equipment in person.

Back