Two-phase Flow in Liquid Nitrogen Pipeline

02 September 2025

Is inconsistent LN2 supply causing variability in your process results? The core challenge lies in managing the problematic two-phase flow property of liquid nitorgen.

How two-phase flow condition occurs in liquid nitrogen pipelines

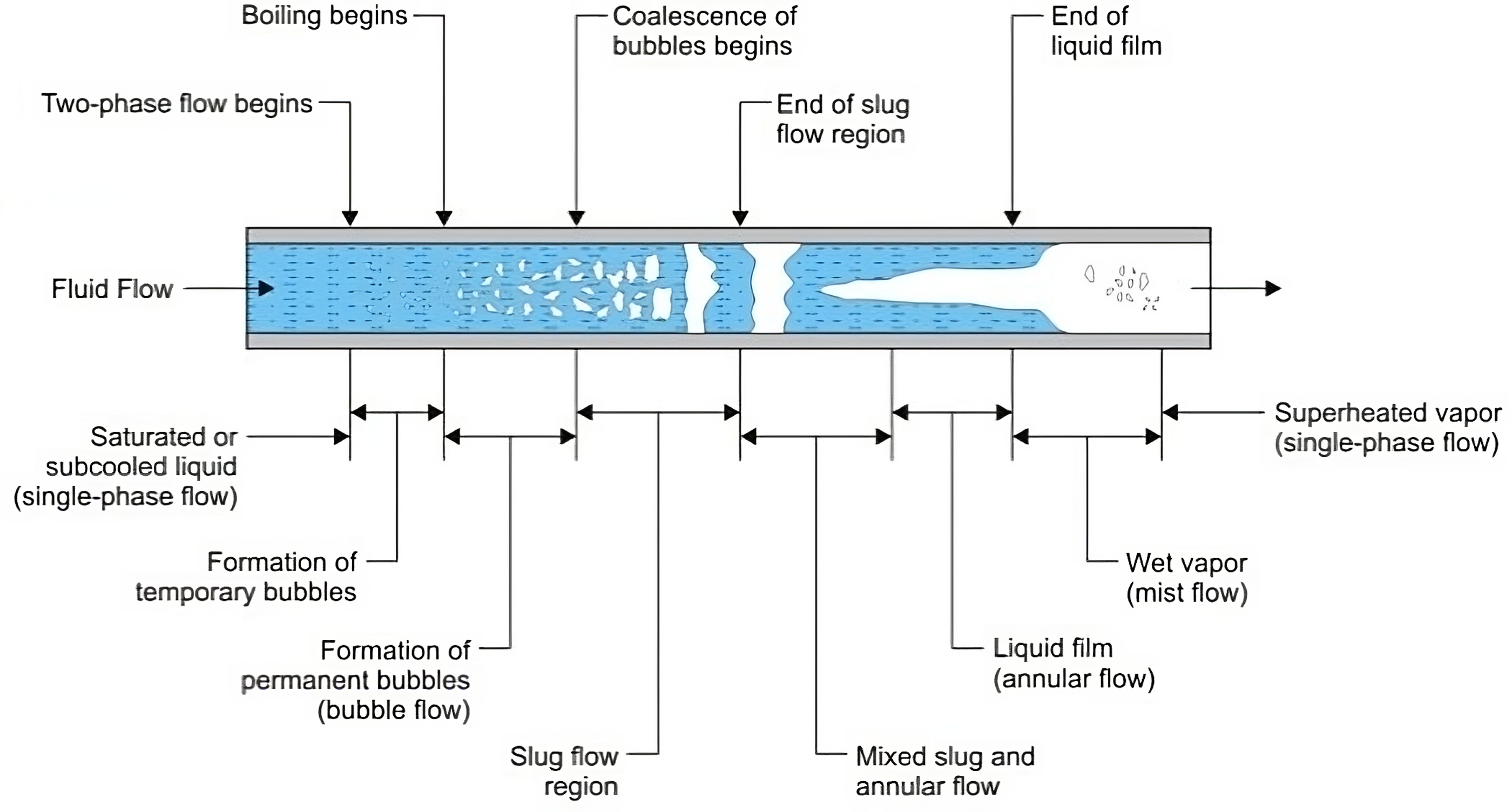

The liquid nitrogen is stored in a bulk storage tank at various saturation pressure, usually between 5 to 10 bars (80 to 150psi). The saturated liquid is drawn from tank and transferred via vacuum jacketed pipelines to the point of use (POU) at the production floor. Liquid nitrogen travels through the pipelines will picks up energy incrementally due of presence of heat leaks, surface friction and turbulence at bends. Depending on the amount of the energy absorbed, the liquid enthalpy increases and vapor is formed creating gas bubbles in liquid stream, resulting in 2-phase flow conditions as shown in diagram below.

Two phase flow in liquid nitrogen pipeline resulted in the following problem:

1. Unstable pressure, flow, temprature and cooling capacity

2. Excessive cryogen boil-off

3, Increase in LN2 consumption & OPEX

Appropriate conditioning equipment are used to remove the vapor from 2-phase liquid to provide users with single phase liquid supply. There are few types of conditioning equipment available for use. The cryogenic process engineer will determine 2-phase flow conditions by quantifying the heat leaks amount and pressure drop within the pipelines. Proper equipment selection and choosing the right location to install in the pipeline will ensure LN2 transfer system works properly to deliver required liquid quality to each point of use (POU).

Example: Liquid nitrogen latent heat of evaporation is 43 Watts-hr/liter and a typical heat leaks for a 200 meter run of 1.5" VJ pipelines is summed up to about 300 Watts, which results in 7 liters of liquid nitrogen boil-off. Because a unit of liquid volume will evaporate into vapor volume between 100 to 600 times, it is very importance to place the conditioning equipment at appropriate interval along the pipeline to remove the vapor soon enought before the liquid in the pipeline turn into slug flow or wet vapor (mist flow).

CSM Conditioning Equipments to overcome two-phase flow

CryoVent constantly removes vapor when the liquid in the pipeline is not in used. The static heat leaks will constantly evaporate the liquid in the pipeline into vapor, the vapor vent job to remove and exhaust the vapor to atmosphere in order to keep the pipeline always filled with liquid. It is sometimes known as keep-full device. It is important to estimate correctly the static heat leaks and system head loss to determine the right number of vapor vent devices required throughout the system. It is installed usually at the highest point of the main-riser pipe or end of header pipes or sub-lateral.

Degasser removes vapor in both conditions, when the liquid in the pipeline is used and not in used. When the liquid is in used, it flows through the degasser where its velocity reduces due to sudden increase in volume. Vapor is removed from 2-phase liquid stream by liquid decompression. It is important to estimate correctly the static heat leaks and head loss of the system to size up the right degasser capacity needed for the intended application.The degasser is usually placed in the middle of the pipeline or at POU.

Phase separator removes vapor from 2-phase liquid stream using the liquid decompression and volume expansion principle by stepping down the incoming liquid pressure. It has storage vessel range from 22 liters to 100 liters capacity. The liquid level and supply pressure are electronically modulated using electro-pneumatic control valves. It is frequently used as pressure step down device to reduce bulk tank pressure to the desired pressure at POU. The unit is supplied with a controller integrated with HMI for ease of pressure & level control setting. An atmospheric pressure control phase separator is capable to provide virtually a subcooled liquid at 1 atm. Atmospheric pressure control phase separator is critical equipment used in molecular beam expitaxy (MBE) application. CSM is one of very few privilege companies in the world possesing the knowledge to design, manufacture & deliver a close loop liquid nitrogen application for MBE system application.